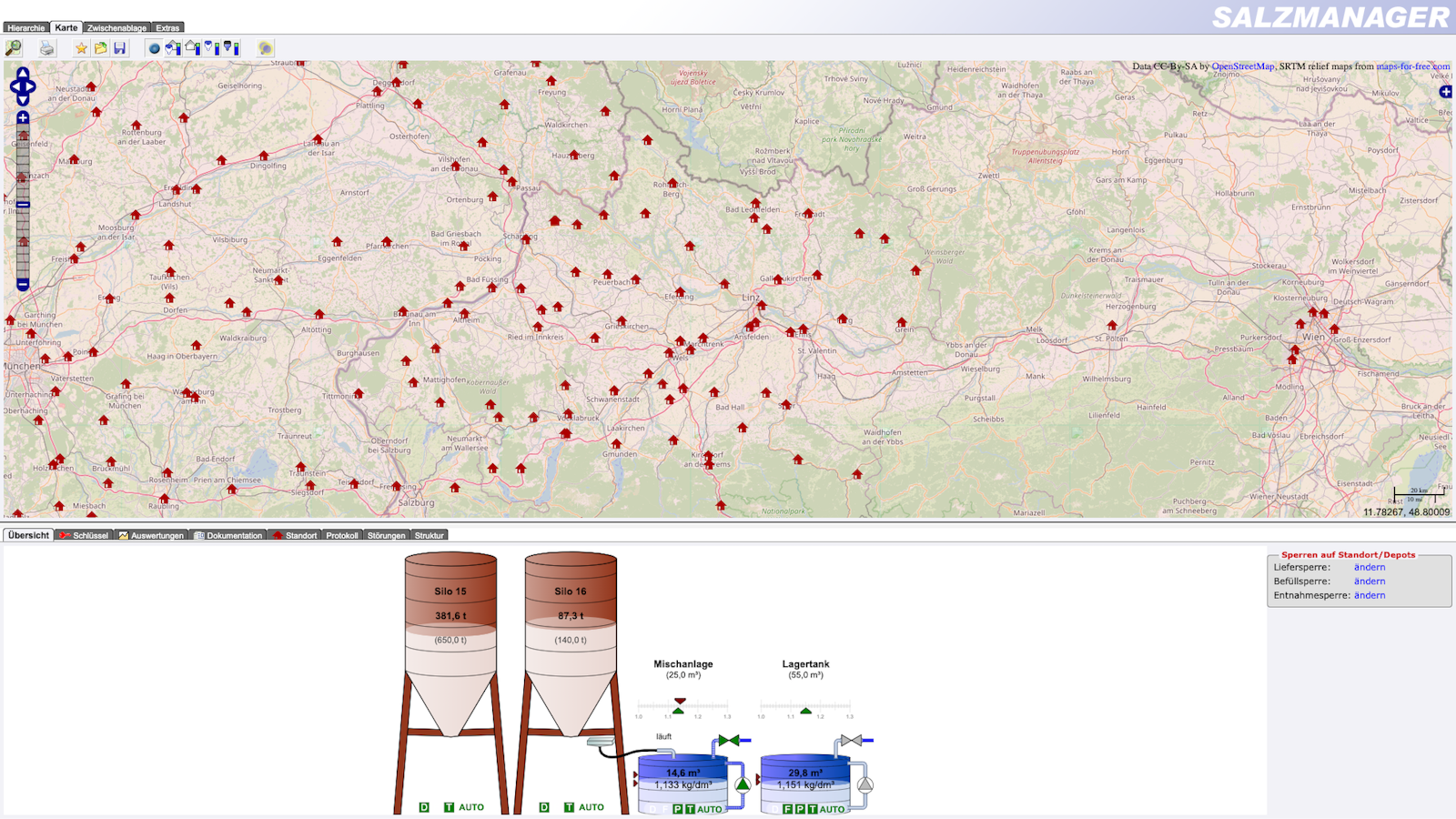

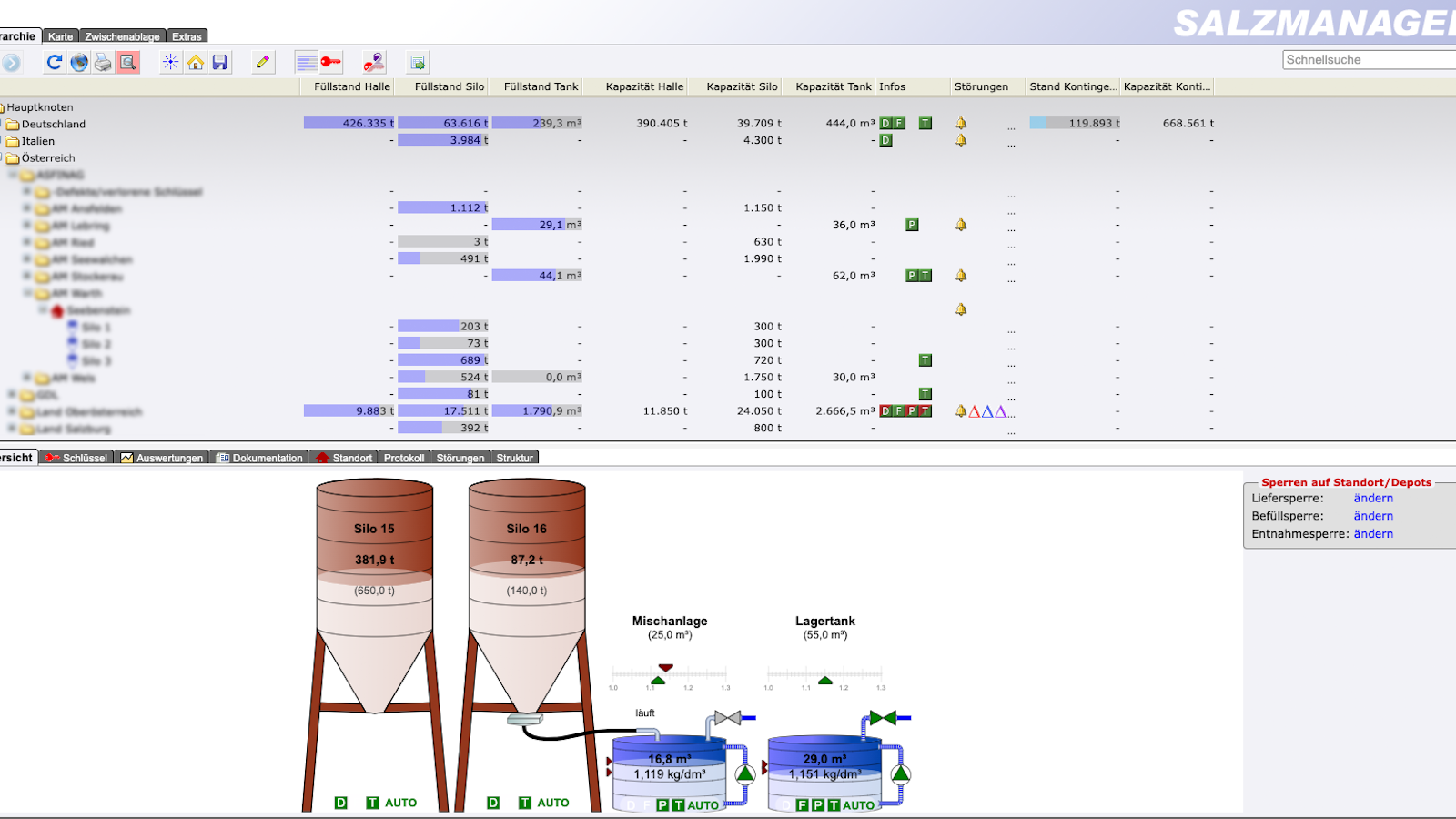

The SalzManager is an administrative system for winter salt and brine management.

Silo and brine levels, changes in capacity due to withdrawals and fillings, level progressions and other data from the integrated facility are stored in a central database.

The SalzManager processes data from various sources: from fully automated locations to manual inputs.

The following web applications are available:

The SalzManager Dashboard with all essential functions - designed for operation with a tablet or smartphone.

The SalzManager Desktop version with full functionality.

Key management

RFID transponder chips function as keys for the various systems. A flexible key management system regulates which actions a key may perform at which system - i.e. the maximum amount of salt or brine which can be withdrawn from a particular site. In addition, the height of the respective vehicle can also be stored so that the windsock automatically adjusts to the correct height.

Salzmanager Mobile key managment

Salzmanager Mobile key managmentUser management

Flexible user applications in the SalzManager ensure that each user only sees the data and locations they are permitted to see.

Automatic reordering

If a plant owner has a corresponding agreement with a salt supplier, it is possible to reorder salt manually or automatically, at the push of a button. For individual customers, an order request system including integration in SAP has also been implemented.

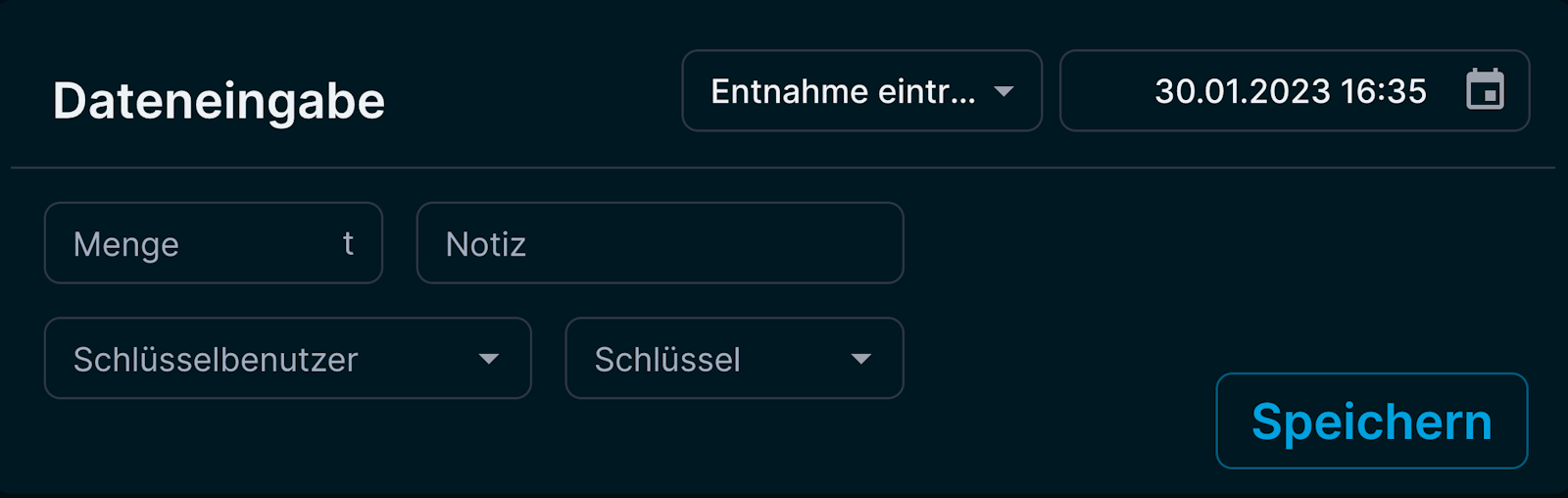

Manual data entry

For silos and tanks that do not automatically feed their data into the Salzmanager, there is the option of manual data entry in SalzManager Dashboard. This means, these storage facilities are also fully integrated and visible in the Salt Manager.

Historical data and progressions

A number of evaluations of the historical data are available for planning. It is also possible to filter data by period, key, location or warehouse.

In the SalzManager Desktop version, there is also the option of exporting all data as an Excel spreadsheet.

Remote maintenance

Remote maintenance can be carried out via Mühlberger Engineering controls on the SalzManager system without the need for a technician to be on site. These controls include:

Remote analysis in real time (control, sensors, devices)

Software updates (also proactive)

Real-time tracking of operations on site (e.g. withdrawals, etc.)

Remote taring of the plants

Direct support for possible technician assignments